Case Study: Microfluidic PCR System

Introduction

We worked as a subcontractor for the University of Hull on their LungCARD project. We were tasked with the whole design, build and commissioning of the bench-top system.

The system had to combine our own custom instrumentation and third party modules, such as the spectrometer. The system featured PCR, X,Y programmable magnet, fibre UV-VIS spectroscopy and 5 channel electrophoresis.

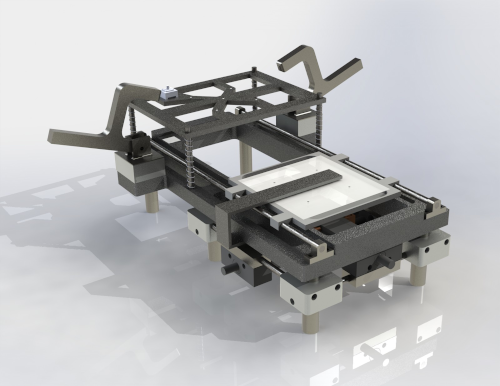

Initially different design variations, using 3D CAD, were presented to the team for assesment before finally building the chosen version. We were responsible for design, build, procurement of parts, installation, commissioning and training.

Key Points

Project Outcome

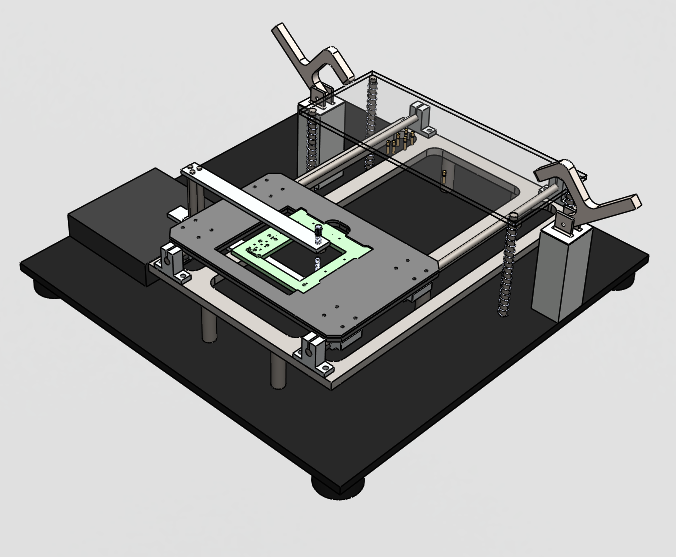

Designing the System

The scientific team and consortium each had ideas on the most optimal way that the system was to be laid out and constructed. There were also some unknowns about the final microfluidic chip dimensions and fluidic paths/layout so an element of flexibility had to be designed into the system from the start.

We used SolidWorks to design a few different iterations/versions of the system based on the groups initial ideas. The process of designing helped everyone visualise the best way version of the system and helped focus the microfluidic chip design.

The Instrumentation

We based the instrumentation on a modular 19" rack system which allowed each instrument or function to have its own slot. This allowed flexibility in the system and modules could be easily changed in the future.

The instrumentation had to incorporate the following:

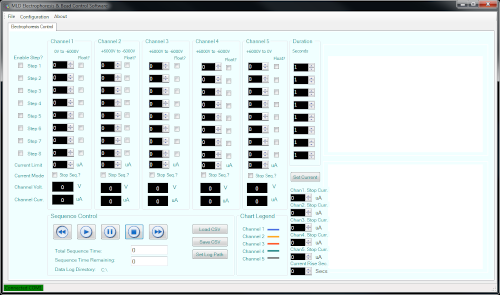

Software

The user interface software was designed to run on a PC and communicate with the system hardware via USB. The software allowed the user to operate the system in manual mode, for performing research. They could set any of the 5 high voltage channels and provide a current limit. They could move the X and Y axis to position the magentic, excite and capature the fluorescence or set the PCR temperature profile. This allowed them to conduct research and move their protocols towards an automated system.

Once they had conducted their research in manual mode they could "write" their protocol as a .CSV or JSON file and load this into the software. The software would then step through the files and read their protocol step-by-step and control the instrumentation and make the necessary measurements and recordings.